Application and sterilization principle of ultraviolet light

发布时间:2021-11-11 09:47

来源:萤光创新

UV dose plays an important role in the sterilization process. Under the condition of sufficient UV dose, inactivated virus bacteria will not revive, but when the dose is insufficient, many virus bacteria inactivated by UV irradiation can repair their damaged structures with the help of light.

Principle of ultraviolet sterilization

According to the wavelength, ultraviolet (UV) light is usually divided into UVA (315nm-400nm), UVB (280nm-315nm) and UVC (200nm-280nm). The wavelength UVC band is also called "solar blind" band. Due to the strong absorption of ozone in the atmosphere, there is almost no ultraviolet light in the near earth solar spectrum.

The main applications of UVC include disinfection / purification of water / air / surface, analytical instruments (spectrophotometry, liquid chromatography, gas chromatography, etc.), mineral analysis. UVC band has short wavelength and high energy. It destroys the molecular structure of microbial body (bacteria, viruses and other pathogens) cells in a short time. By destroying microbial DNA and RNA to prevent its reproduction, it can achieve efficient and rapid broad-spectrum sterilization effect, so as to sterilize water, air and object surfaces, so that cells can not regenerate. Therefore, it is widely used in water Sterilization of air, etc. The data show that with the UV irradiation intensity of 30MW / cm2, almost 100% of the bacteria can be killed in one second. The effect is very significant and can be widely used in the field of medical and health care. In the field of personal health and family hygiene, ultraviolet light can be used for disinfection of water cups, bowls and chopsticks, air purification and sterilization, killing insects, sterilization and deodorization of shoes and socks, disinfection of baby bottles, etc.

Ultraviolet sterilization effect

According to different microbial species, the UV sterilization time and dose are also different. Different bacterial species have different UV absorption peaks. For example, the maximum absorption wavelengths of DNA and Escherichia coli are 265nm, while the maximum absorption wavelengths of Cryptosporidium and phage are 261nm and 271nm respectively. Therefore, the sterilization time should be different. When the ultraviolet radiation intensity is 3 × one hundred and four μ At w / cm2, the time required to kill virus, bacteria, mold spores and algal bacteria was 0.1 ~ 1.0s, 1.0 ~ 8.0s and 5.0 ~ 40.0s respectively. According to Dong Xiaoping, an expert from the Institute of viral disease prevention and control of the Chinese Center for Disease Control and prevention, the research team found that the intensity was greater than 90% μ W/cm2's UVC exposure to coronavirus can kill SARS virus in 30 minutes. UV dose plays an important role in the sterilization process. UV dose can be expressed as the product of UV intensity and irradiation time. Under the condition of sufficient UV dose, inactivated virus bacteria will not revive, but when the dose is insufficient, many virus bacteria inactivated by UV irradiation can repair their damaged structures with the help of light. When the UV dose is the same, the irradiation mode of high intensity, short time or low intensity and long time can be used to achieve the purpose of sterilization. Kill 1 × For 104 Spirillum / ml, the UV dose is about 30 MJ / cm2, while for killing the same number of spores, the UV dose is about 70 MJ / cm2.

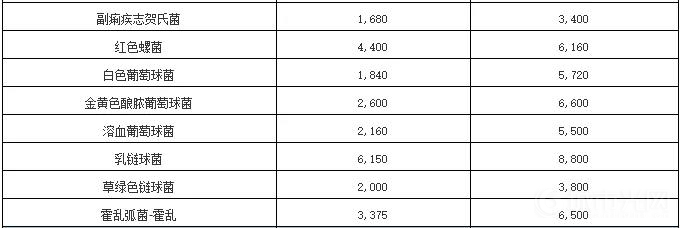

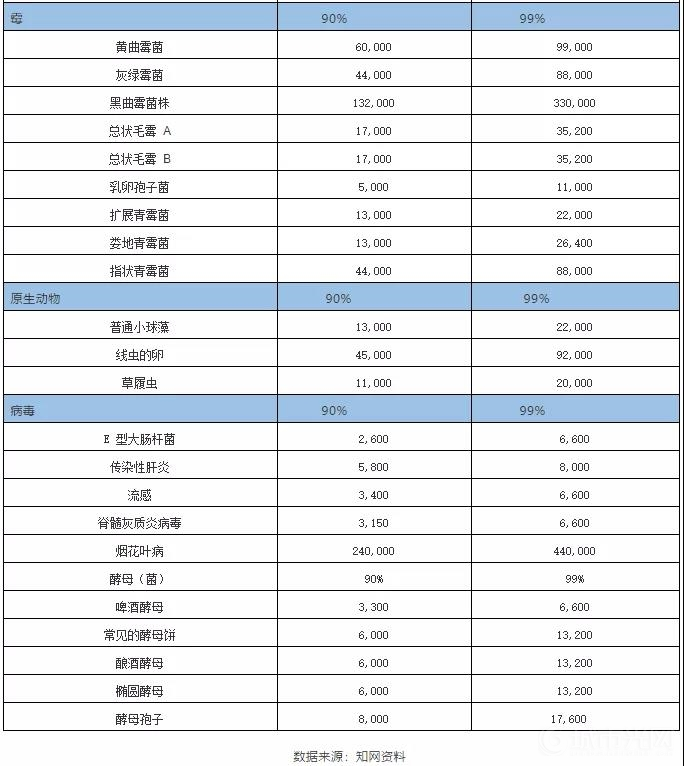

Exposure dose of common ultraviolet sterilization

Application of UV LED disinfection products

UV sterilization and disinfection products are mainly used in three fields: water sterilization, air sterilization and object surface sterilization. With the development of LED technology and the improvement of efficiency, it will gradually replace the traditional mercury lamp light source in these fields from small power to medium power and then to high power.

Water disinfection field

Water disinfection is a typical multi-disciplinary terminal application. The technologies required for its product design include optical design, thermal design, material matching, part assembly and many other technologies. As the most mature and effective application of UV LED, water sterilization module can be divided into static water sterilization and flowing water sterilization.

1. Static water sterilization static water sterilization refers to the sterilization and bacteriostasis of the water in the water storage space (container). Because the water storage container is usually static for a long time, it will be easy for bacteria to breed and cause excessive bacteria under the condition of appropriate temperature. In view of this situation, the static water sterilization module enables it to reach and maintain a low bacterial level by regularly opening sterilization. According to the sterilization orientation of the product, it is divided into bacteriostasis and sterilization. There is no essential difference between sterilization and bacteriostasis. Its fundamental purpose is to keep the affected water sterile or low bacterial level for a long time.

Through in-depth strategic cooperation with high-quality light source manufacturers at home and abroad, Qingdao fluorescent innovation produces customized light sources according to sterilization needs, so as to achieve reasonable matching between sterilization and light sources. At present, the light source output, stability and service life of the company's products have reached the domestic leading level.

2. Flowing water sterilization. Flowing water sterilization is different from static water sterilization. Through the high-power ultraviolet radiation unit, the water body passing through the sterilization module can be sterilized efficiently and instantaneously, so that the water body passing through the sterilization module can reach a level of sterility or extremely low bacterial content.

Qingdao fluorescent innovation has developed a variety of over-current sterilization modules in combination with practical application scenarios. It mainly includes: ultra micro over-current sterilization module, aiming at the scene where the sterilization demand is less than 500ml / min. Micro sterilization module, 500ml ~ 1L / min standard sterilization module: suitable for 1L ~ 2L / min mobile enhanced sterilization module: suitable for 2L ~ 4L / min mobile water sterilization, large and super large sterilization modules: suitable for more than 10L ~ 500L / min mobile water sterilization. It is noteworthy that in order to completely solve the hidden danger of exceeding the standard of bacterial colonies in drinking water sterilization, fluorescent innovative technology has developed sterilization faucets and sterilization faucets. The sterilization function is cleverly integrated into the faucet and faucet of the water purifier (water dispenser), so as to achieve real terminal sterilization, and the inlet is after sterilization. The problem of secondary pollution has been really solved.

Air sterilization field

UV air purification mainly adopts UVC sterilization and UVA photocatalysis. UVC air sterilization purifier mainly follows the principle of ultraviolet circulation disinfection of air, that is, under the action of the fan, the wind passes through a closed pipe. At the same time, the ultraviolet lamp irradiates the air passing through the pipe to complete disinfection. At present, the ultraviolet air sterilization machine is mainly used in hospitals, laboratories and other special application places. UVA photocatalytic air purifier uses the principle of photocatalysis to decompose organic pollutants in the air and kill bacteria and viruses. In terms of dynamic air disinfection, it is difficult to use ultraviolet light source alone, and HEPA filtration and adsorption materials are also needed to improve the sterilization rate.

Surface sterilization field

The epidemic has stimulated the application of UV LED sterilization products in personal and household consumer goods. Small power products such as sterilization bags, sterilization boxes and sterilization sticks emerge one after another. New application products in the fields of elevator handrails, cold chain logistics and express packaging are in the process of R & D and development.

Qingdao fluorescent Innovation Technology Co., Ltd. has a professional postdoctoral team, focusing on the research of ultraviolet sterilization application. After years of deep cultivation in the ultraviolet industry, the company has obtained a number of national invention and utility model patents. At present, a number of sterilization module products have been put into the market. For more details, you can browse the company website www.qdyingguang.com, contact the company for WeChat's official account.

Keywords: UVC, UVC led, deep UV, UV sterilization, deep UV LED, water sterilization, water disinfection, air sterilization, air purification, flowing water sterilization, static water sterilization